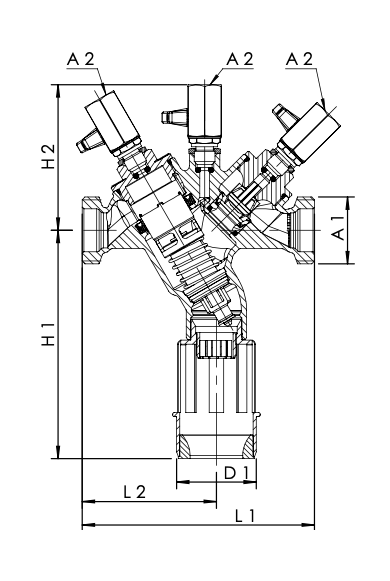

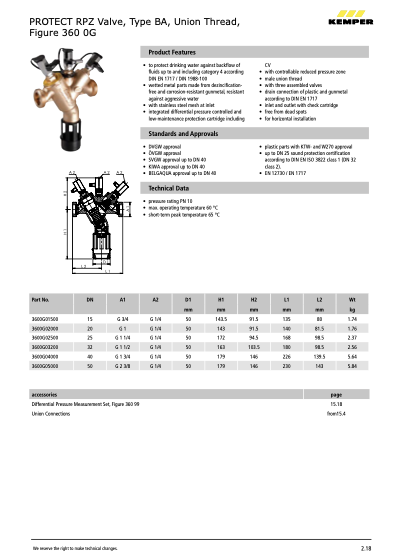

🔐 Ensuring Water Safety with Kemper PROTECT RPZ Valve, Type BA, Union Thread, Figure 360 0G! 🔐

✅ What's Unique?: Hanley Controls stands out by offering comprehensive commissioning and servicing for these specialized valves. Our expert team ensures seamless integration and ongoing maintenance, guaranteeing optimal performance and compliance.

✅ Reliable Protection: The Kemper PROTECT RPZ Valve is engineered for robust backflow prevention, safeguarding water quality in commercial and industrial environments. With Hanley Controls' expertise, you can trust in reliable water safety solutions.

✅ Why Choose Us?: We're dedicated to delivering top-notch service and support, backed by years of experience and technical proficiency. Partner with Hanley Controls for peace of mind and unparalleled reliability.

Explore more about the Kemper PROTECT RPZ Valve and our specialized services:

Contact Noel O'Neill (email: noel.oneill@hccl.ie) today to discuss your water safety needs and how Hanley Controls can assist you!

Product Features

|

|

|

|

|

|

RSS Feed

RSS Feed