| Embark on a journey of innovation and reliability with Hanley Controls, where we redefine the standards of pneumatic solutions. With a comprehensive range of high-quality products and unparalleled expertise, we are your ultimate partner in fluid control needs. From fittings and tubes to compressors and safety solutions, we offer a diverse array of offerings tailored to meet the demands of various industries. At Hanley Controls, excellence is not just a goal; it's our commitment. Join us and discover the power of pneumatic excellence today! |

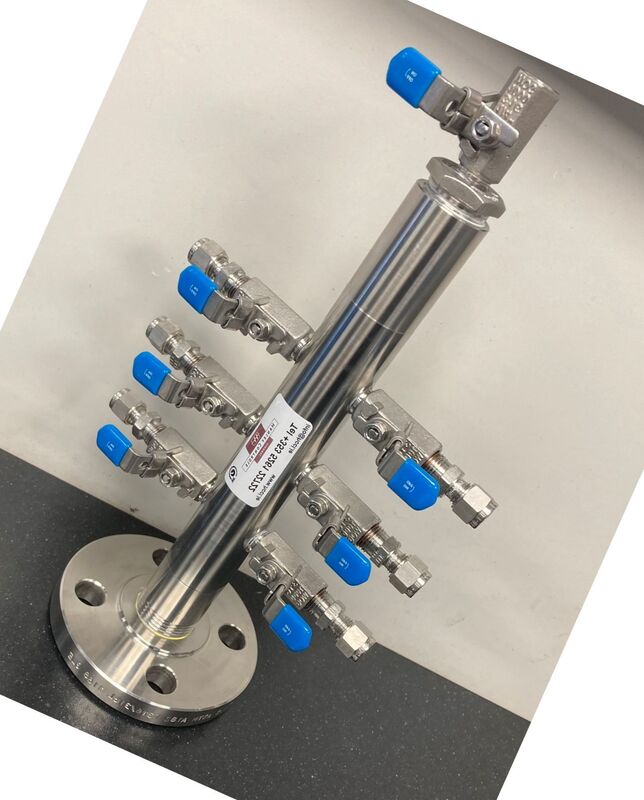

1️⃣ FITTINGS/TUBE, COUPLINGS & PIPEWORK: We provide high-quality fittings, tubes, couplings, and pipework to meet your fluid control needs.

2️⃣ CYLINDERS / ACTUATORS: Our cylinders and actuators are designed for precision and reliability in various applications.

3️⃣ PNEUMATIC CONTROL / SOLENOID VALVES: Explore our wide selection of pneumatic control and solenoid valves for efficient operation.

4️⃣ PROCESS CONTROL/SOLENOID VALVES: Enhance your process control with our top-notch solenoid valves.

5️⃣ AIR TREATMENT: Ensure clean and dry air with our advanced air treatment solutions.

6️⃣ MACHINE AUTOMATION: Streamline your operations with our machine automation products tailored to your requirements.

7️⃣ TOOLS & AIR MOTORS: Discover our range of tools and air motors for various industrial applications.

8️⃣ PNEUMATICS- PUMPS-VACUUM/DIAPHRAGM: We offer a comprehensive selection of pneumatic pumps, vacuum solutions, and diaphragm products.

9️⃣ VACUUM: Find the right vacuum solutions to optimize your processes and productivity.

🔟 COMPRESSORS: Explore our efficient and reliable compressors to meet your compressed air needs.

1️⃣1️⃣ SERVICE: Our dedicated service team is here to provide support and assistance whenever you need it.

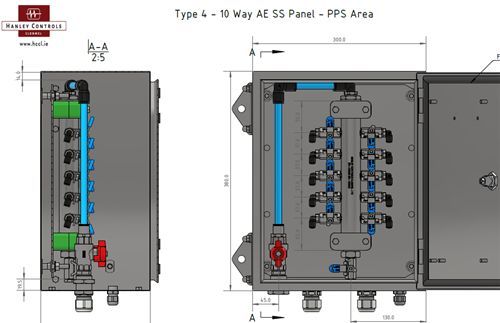

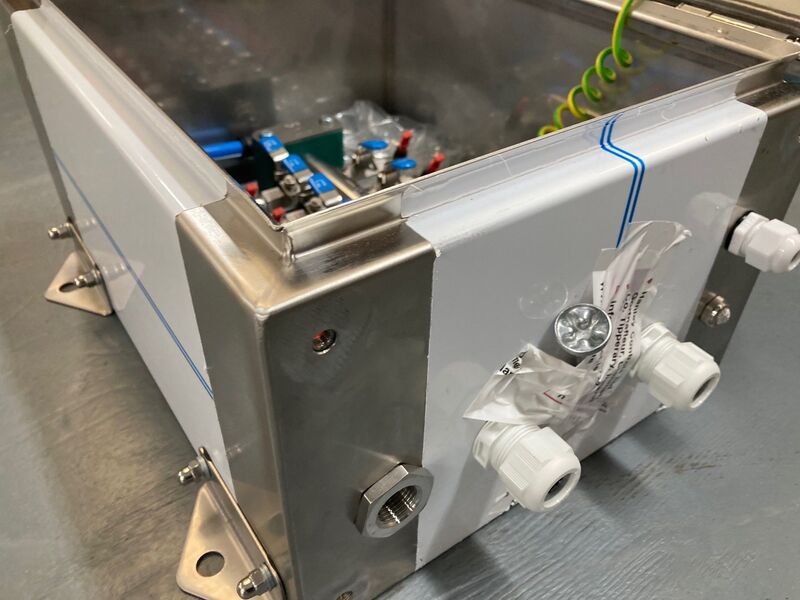

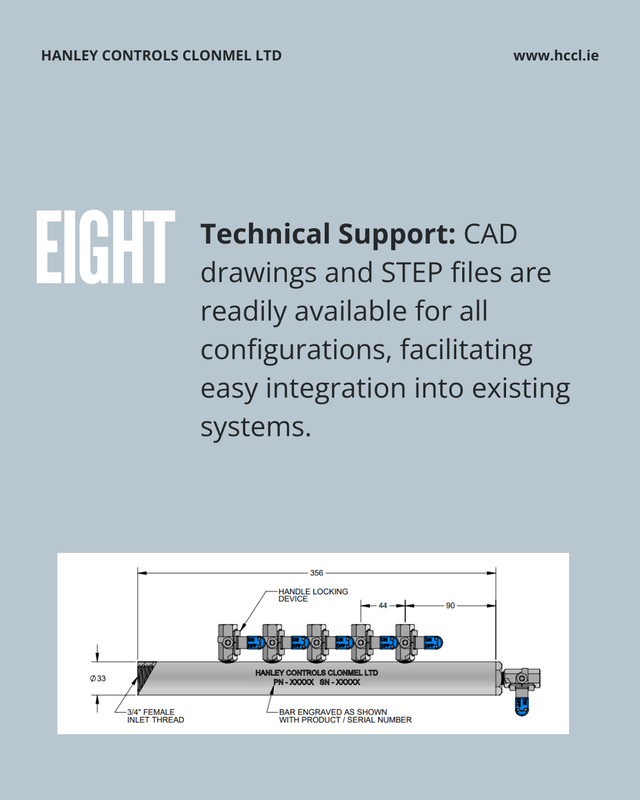

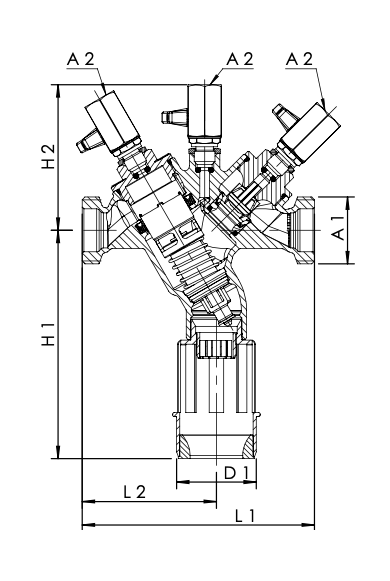

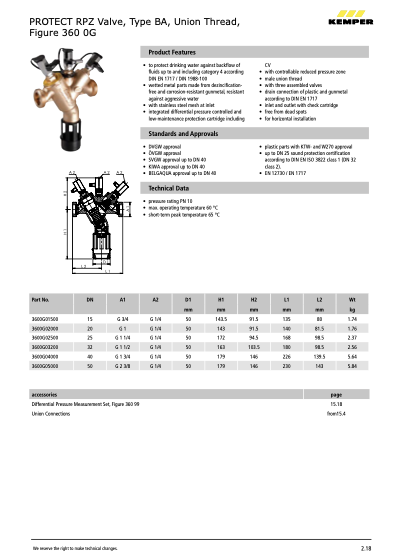

1️⃣2️⃣ Fluid Power Safety Solutions: Safety is paramount, and we offer a range of solutions to ensure fluid power safety in your operations.

At Hanley Controls, we're committed to delivering excellence and innovation in every product and service we offer.

Contact us today to learn more about how we can support your pneumatic needs or view more here: https://lnkd.in/eYXM8zpa

Contact Seán Brennan (email: sean.brennan@hccl.ie) or Martin Ralph (email: martin.ralph@hccl.ie)

RSS Feed

RSS Feed