| For 30+ years now Hanley Controls Clonmel has been Manufacturing/supplying a large range of Stainless steel Air Distribution Manifolds for: ✓ petro-chemical ✓ pharmaceutical ✓ biopharmaceutical industries ✓ Food & Beverage We supply: ✓ a full range of associated tube and fittings ✓ including Parker Anti Spark prestoweld PU airline ✓ stainless steel tubing and Parker Legris Push in ✓ A-lok compression fittings. |

|

Manifolds are suitable for instrument hook-up, and available with variety of options on the inlet and outlet side including Parker Regulators and FRL.

0 Comments

The Series IEF is composed of a 316 stainless steel body shaft, fitting, and electrodes. It has been designed for a long lifecycle with minimal maintenance. This transmitter utilizes no moving parts that could potentially break and has electrodes that discourage fouling. It is also certified to NSF/ANSI 61 and 372 standards, making it ideal for measuring flow in drinking water system components. Field configurable, integral, or remote setup displays allow for ultimate flexibility. By accommodating a variety of application configurations with one model and multiple display configurations, the Insertion Flow Transmitter is an extremely versatile instrument. It includes display selectable BACnet and Modbus® communications. The Setup Wizard and installation tool are simple to use for a quick and accurate installation. The installation can be simplified further using the accessory setup kit. The kit ensures exact installation application depth by providing all the necessary tools, such as: a circumference tape measure, ultrasonic pipe thickness gauge, and portable programmer for non-display units.

What factors should you consider when selecting a regulator?

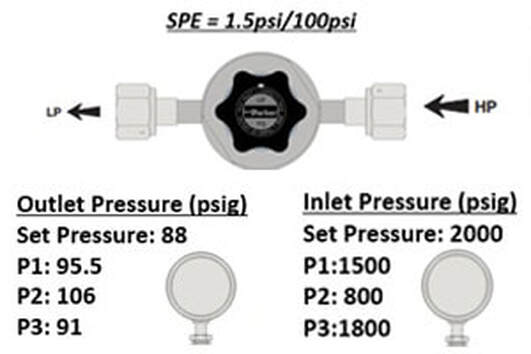

Inlet and outlet pressure Knowing the upstream and downstream pressure requirements of your line or system sets the pressure envelope, narrowing down the field of regulators to choose from. Ensure you know the application's operating pressure range and maximum pressure for both the inlet and outlet. Key considerations:

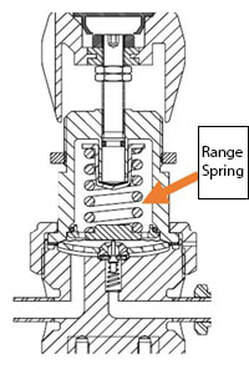

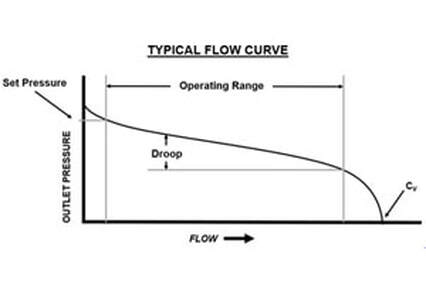

Outlet Pressure – The outlet pressure range of a regulator is determined by the range spring. A lower outlet pressure range would have a “lighter” spring, while a higher outlet pressure range would have a “heavier” spring. Sensitivity – The amount of spring force produced by the range spring directly correlates to flow performance and adjustment resolution of outlet pressure. Lighter springs generally produce less pressure drop at flow and provide a finer resolution of pressure adjustment. Therefore, sizing a regulator for an application is critical to achieving optimal performance. Selecting a regulator tailored to the application by rounding up the outlet pressure target to the nearest outlet range option is ideal for proper sizing. Systems can also have varying operating pressures when being fed by multiple regulators. Especially if the range of varying operating pressures is wide, it is inadvisable to go with a “one-size fits all” selection approach. High-outlet pressure ranges may not be suitable for low-pressure applications due to the level of sensitivity. It may not allow the precise adjustability needed to reach a target outlet pressure. In addition, a high-pressure regulator in a low-pressure application will experience a greater amount of pressure drop at flow.

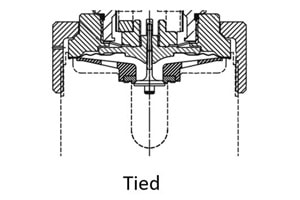

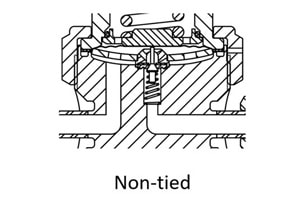

System temperatureProcesses can reach extremes in temperatures, especially due to changes in pressure. Your choice of regulators must withstand the ranges of temperatures that occur in typical operating conditions. System temperature and media determine the most suitable seal material option for your application. If the system operating temperature exceeds the limit of seal materials ratings, it can cause leaks internally and/or externally, which create safety hazards and significant downtimes. System mediaThe type of system media (gas, liquid, or steam) along with temperature will affect the longevity of the regulator you select. Surface treatments such as electropolish and passivation, in addition, to surface finish, can enhance corrosion resistance and cleanliness with stainless steel regulators. Another consideration is seal materials. Metal regulators are especially affected since they are typically designed with plastic or rubber seals. Knowing media compatibility will influence the decision on the best seal material choice. Media that is not compatible can cause faster deterioration and decrease the life cycle, making the material compatibility between your regulator and your system media a key consideration. End connections End connection types are usually synonymous with the industry served and the means to provide the level of leak integrity needed. For example, ultra-high purity regulators used for semiconductor processes commonly have welded face-seal or tube-end connections due to more stringent leak rates. On the other hand, regulators for oil and gas industries commonly use National Pipe Thread Tapered (NPT) connections. Tied vs. non-tied diaphragm Tied diaphragm regulators physically connect the poppet to the diaphragm, resulting in a mechanically assisted positive shut-off acting as a safety shut-off feature in the event there is leakage across the seal. Tied diaphragms allow the spring to be removed from the wetted area, making the operation far cleaner and reducing particles that could be generated during operations. Therefore, tied diaphragms are preferred in ultra-high purity (UHP) applications. In applications with hazardous and corrosive media, tied diaphragms are considered an added safety feature. However, a tied diaphragm costs more due to the increased number of components. Other factors to consider

Conclusion

No matter what your application is, choosing the proper regulator is vital. Your regulator supplier can help with the selection process by providing pressure and flow requirements, sizing information, temperature ranges, and other essential information. Key Takeaways:

As flow control subject matter experts for nearly 30 years, Parker Veriflo can help you start the regulator selection process. CONTACT US To learn more about pressure regulators and get expert help, contact Noel Walsh [email protected]

|

AboutWelcome to the news feed of Hanley Controls Clonmel Ltd. Find out about new products, news, events, offers and more. Archives

July 2024

Categories |

RSS Feed

RSS Feed