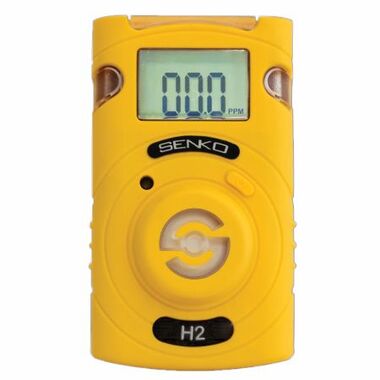

Easy to Use Personal Detection This H2 Gas Monitor, unlike most others on the market, keeps the user informed on the current gas concentration in the atmosphere at a glance. With a backlit display for all environments, it also offers audible and vibration alarms. This clear and concise system ensures you are always informed on the current Hydrogen concentration around you. Alarm and data log information is easily downloadable via pc software as well as the products simple user interface. This product has a small format with an alligator clip and one button operation. Thus, significantly reducing training time along with guaranteeing ease of user utilisation. Versatile for Your NeedsThis no-nonsense Hydrogen detector can be used in an array of industries and environments, including Hydrogen fuel source, cryogenics, steel works, Hydrogen battery technology and refineries. In addition, the 0-100ppm range makes it ideal for personal protection due to its low sensitivity. The SGT-P single gas monitor can also be used for a variety of gas detection. This including Oxygen (O2), Hydrogen Sulphide (H2S), Sulphur Dioxide (SO2) and many others. This product has a Hydrogen sensor built to last 3-5 years and a 24-month warranty, offering traceable calibration and servicing from IGD. Ensuring extra care even after the initial purchase.

Measuring liquid concentration to control and optimize chemical industry operations with Vaisala5/3/2022 Measuring liquid concentration or density in-line is important in the chemical industry as density variations have impact on both raw materials and finished products. Process safety is also mandatory, since hazardous chemicals represent a potential risk to people and the environment. While managing these challenges, chemical manufacturers strive to produce high-quality products that meet customers’ specifications. To achieve these goals, accurate process measurements, high process efficiency, low energy consumption, and state-of-the-art process control management are crucial. In-line measurement of liquid concentration and density directly in chemical processVaisala K‑PATENTS® process refractometer is designed to measure and indicate inline liquid concentration of almost any chemical or compound.

The refractometer can be installed cost-efficiently in the main processing line, bypass line or vessel to control the raw and in-process materials in order to extract their maximum value and achieve high quality end products. The performance of all types of chemical refining, manufacturing, and quality-control operations can be dramatically improved with Vaisala’s refractive index measurement technology – whether they are in continuous or batch processes. Unlike intermittent sampling, continuous monitoring provides instant feedback on changes in the process, and this data can enable real-time and precise process control of the common chemical industry operations, e.g.:

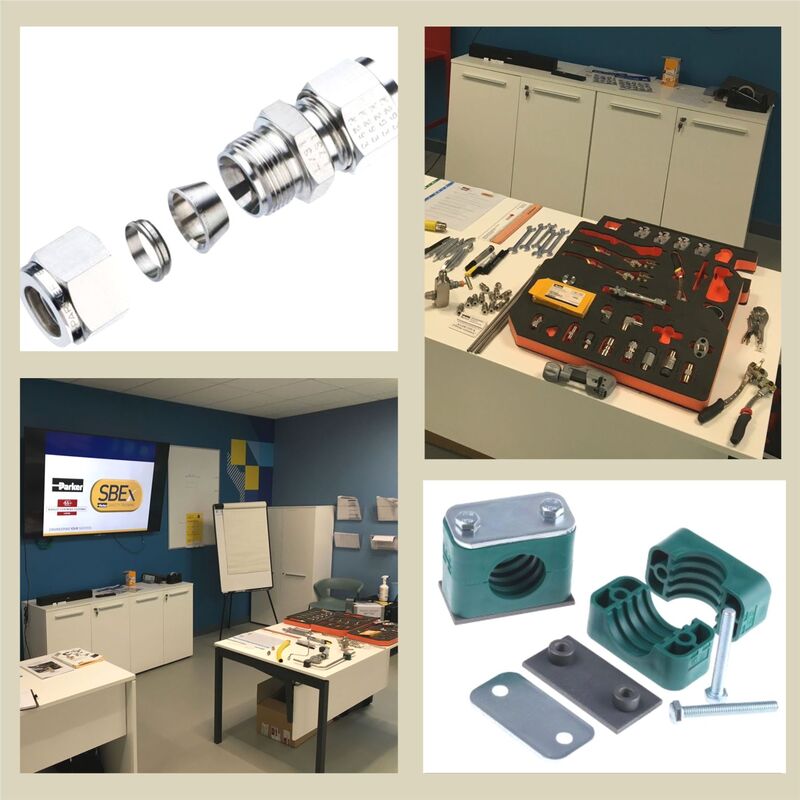

A recent Parker SBEX training course Hanley Controls (Clonmel) Ltd. did at our customers location. The site is using a large qty of our PARKER A-LOK fittings, valves, Instrument tube & Clamps range. With a number of new starters on this phase of the Pharma project we agreed it would be good practice and good investment for all involved to have every installer take part in the course. The key elements/goals of the course are as follows:

•Increase understanding of SBT systems and components •Improve SBT systems Safety •Enhance SBT systems Integrity •Reduce Production losses •Augment skills and confidence whilst working on SBT systems •Practical training on Fittings assy, tube bending & Clamping Official Parker certification provided for all who attend and progress in the course. Training can be held at Hanleys training room or at a customers site. For more information pls contact us or visit our website here to view our products/equipment. 052 6122722 [email protected] https://lnkd.in/dbNDP9f |

AboutWelcome to the news feed of Hanley Controls Clonmel Ltd. Find out about new products, news, events, offers and more. Archives

July 2024

Categories |

RSS Feed

RSS Feed