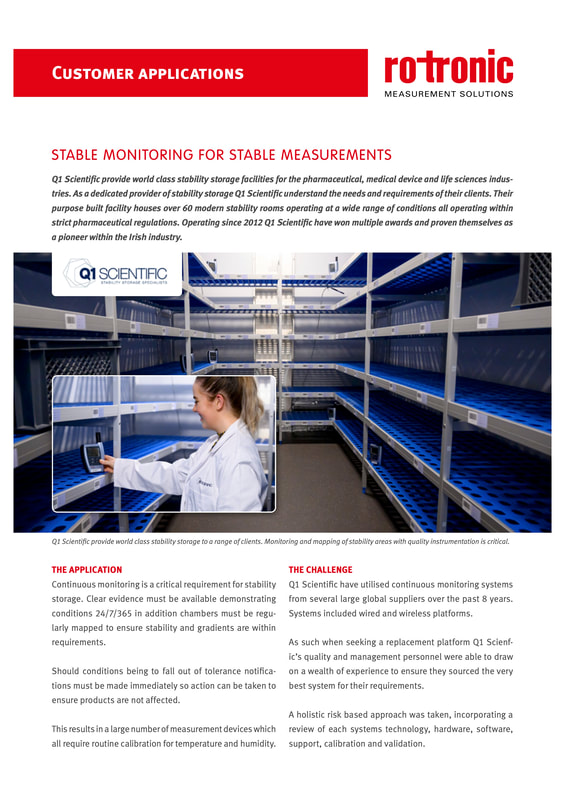

| THE APPLICATION Continuous monitoring is a critical requirement for stability storage. Clear evidence must be available demonstrating conditions 24/7/365 in addition chambers must be regularly mapped to ensure stability and gradients are within requirements. Should conditions being to fall out of tolerance notifications must be made immediately so action can be taken to ensure products are not affected. This results in a large number of measurement devices which all require routine calibration for temperature and humidity. | THE CHALLENGE Q1 Scientific have utilised continuous monitoring systems from several large global suppliers over the past 8 years. Systems included wired and wireless platforms. As such when seeking a replacement platform Q1 Scienf- ic’s quality and management personnel were able to draw on a wealth of experience to ensure they sourced the very best system for their requirements. A holistic risk based approach was taken, incorporating a review of each systems technology, hardware, software, support, calibration and validation. |

• Full FDA 21 CFR Part 11 and EU Annex 11 compliance • Designed ground up to comply with and be used within validated GxP applications

• Simple tools for data analysis designed around audits and assessments

• Configurable scripts to test core functions with clear reports

• Ongoing software development following

GAMP5 process

• Validation Support

• Clear validation documentation including detailed system risk assessment

• Comprehensive eCompliance White Paper detailing how RMS meets regulatory requirements\Access to a network of validation engineers specialising in system validation

RSS Feed

RSS Feed