“We knew that K-PATENTS customers are able to trust the data from their refractometers, and we were very impressed with the company’s experience and expertise in liquid measurements,” explains Jutta Hakkarainen, Director, Liquid Measurements at Vaisala. “Application expertise, measurement accuracy and long-term reliability are also family traits at Vaisala, but excitingly, we could see enormous growth potential for this technology, so it made perfect sense to put the global power of Vaisala behind it, in order to realise that possibility.”

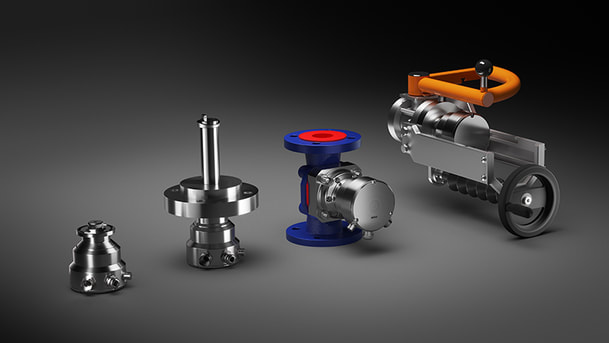

In February 2023, following a long period of consultation with customers and after a meticulous engineering review of the refractometer range, Vaisala announced the launch of Polaris™ - the latest generation of inline refractometers. The new Polaris™ instruments offer outstanding levels of performance, as well as compatibility with Vaisala’s family of high-quality Indigo industrial transmitters for data logging and display, prism wash control, instrument configuration, security, etc. “This new range of refractometers has been designed to meet the most demanding application requirements; providing accurate, reliable, inline liquid measurement technology for a wide variety of industrial sectors,” explains Hakkarainen.

Inline refractometers are used in a wide variety of industries, including food, beverage, brewing, dairy, pulp and paper, pharmaceutical, semiconductor, chemical, petrochemical refining, and textiles. However, in order to determine which processes are suited to refractometry, it is important to understand how this technology works.

Refractometers measure the Refractive Index (RI) of a liquid, which is the critical angle of refraction of light in a process medium. The critical angle is that from which the total reflection of light starts. Concentration values can be determined from the RI measurements taking pre-defined process conditions into account. Vaisala’s Polaris™ refractometers are therefore supplied factory calibrated to meet specific process requirements.

The most obvious applications for inline refractometers are those with binary solutions, where one (highly refractive) component is dissolved in a solvent, such as sugar in water. Consequently, one of the most common applications for Vaisala’s refractometers is the continuous measurement of Total Solids (TS) and Brix (dissolved solids) concentrations in beverages. Of course, inline refractometry is also suited to applications with multiple constituents, where process managers need to monitor aggregated changes in the levels of (refractive) components.

Dairy processing is a good example of an RI application with multiple dissolved and suspended constituents. For example, the milk standardisation process produces whole milk that has a standardised minimum fat content, while also producing the cream (fat) by-product that can be used for secondary products such as butter, cream, yoghurt and cheese. During standardisation the milk components (fats, solids, proteins, non-fat solids, and total solids) are adjusted to the required levels. The refractometer is installed after the hydration tank to measure the concentration of all dissolved solids; enabling automated control of the standardisation process.

Another dairy process, homogenisation, reduces the particle size of the fat globules in milk so that they stay evenly distributed. Here, a refractometer is installed after the homogeniser to ensure a reliable measurement of the milk’s total solids (including fat content) and to enable better control of fat and dry matter content after standardisation.

A further example of a refractometers monitoring liquids with multiple components, is the brewing of beer, where RI measurements improve almost every stage of the process. To ensure a consistent wort output, refractometers measure the mash concentration in water at the outlet pipe. Concentration measurement during lautering allows the detection of the correct shut-off point for rinsing, and during wort boiling continuous measurements of wort strength/gravity enable the brewer to determine exactly when the wort has reached the required strength.

In the paper and pulp industry, black liquor is a multicomponent by-product of the kraft process, which converts wood into wood pulp. Black liquor is an aqueous solution of lignin residues, hemicellulose, and the inorganic chemicals used in the process. Here, Vaisala refractometers are used for measuring black liquor dry solids, liquid density, feed liquor concentration and green liquor Total Titratable Alkali (TTA) and density in the chemical recovery process. These measurements enable process optimization and increase the capacity of the evaporators. In addition, the quality of white liquor can be improved by continuously controlling the TTA of the green liquor in the causticizing process. As well as improving the efficiency of the paper mill, refractometers also enhance the safety of the process to feed black liquor solids to the recovery burners.

Continuous RI data is particularly useful where process operators are looking for a specific change in the RI measurement. For example, as well as using refractometers for quality control monitoring, beverage manufacturers also use them to ensure correct product-to-packaging selection. Similarly, refractometers are used to monitor beverage factory filling lines by instantly detecting product-to-product and product to-CIP cleaning interfaces, allowing efficient change-over between products or batches. The response speed of the refractometer means that the interfaces (between product/cleaning chemicals/water), can be detected very quickly, which avoids waste and ensures that no product contamination occurs.

| Refractometry vs other measurement methods At the risk of stating the obvious, continuous monitoring is preferable to laboratory analysis for the vast majority of process control applications. This is because sampling only provides a retrospective indication at one moment in time, the process is laborious and costly, and by the time the results are available they may no longer be applicable. Some supposedly online measurement technologies also incur a delay because they involve the creation of a sample which is then passed through a multi-stage process. As a result, there is a delay in the availability of a measurement, which may not be permissible in many process control applications. |

Each method comes with advantages and disadvantages, so it is necessary to choose a technology that is best suited to the application. Vaisala therefore provides a global team of process monitoring experts that can provide appropriate help and advice.

Summary

This article has alluded to a few of the many applications for which Vaisala’s refractometers are helping to improve the quality and consistency of production, whilst lowering costs, optimizing processes and reducing waste. The ideal processes that can benefit from Polaris™ technology can be summarised as those in which changes in the RI of the process liquid can be translated into valuable process data.

“The benefits of Polaris™ refractometers extend beyond useful process measurements,” explains Jutta Hakkarainen. “This is because they come with the accuracy and long-term reliability that Vaisala customers expect. In contrast with many other inline measurement instruments, Polaris™ refractometers are simple to operate and maintain, and they are insensitive to flow rate, suspended solids, crystals, bubbles, entrained gases and sensor coating. It therefore seems unlikely that they will remain a secret for much longer.”

Refractometry vs other measurement methods

At the risk of stating the obvious, continuous monitoring is preferable to laboratory analysis for the vast majority of process control applications. This is because sampling only provides a retrospective indication at one moment in time, the process is laborious and costly, and by the time the results are available they may no longer be applicable. Some supposedly online measurement technologies also incur a delay because they involve the creation of a sample which is then passed through a multi-stage process. As a result, there is a delay in the availability of a measurement, which may not be permissible in many process control applications.

A variety of process measurement techniques are available, and the choice of technology will depend on the process. Density and RI instruments measure liquid concentration and composition. Density meters employ, among others, Coriolis, microwave, ultrasonic and nuclear techniques. Each of these can provide useful measurements in some applications, but their accuracy can be affected by air bubbles, particles, impurities, deposits, solids, flow variation, vibration, temperature, and turbulence.

Each method comes with advantages and disadvantages, so it is necessary to choose a technology that is best suited to the application. Vaisala therefore provides a global team of process monitoring experts that can provide appropriate help and advice.

Summary

This article has alluded to a few of the many applications for which Vaisala’s refractometers are helping to improve the quality and consistency of production, whilst lowering costs, optimizing processes and reducing waste. The ideal processes that can benefit from Polaris™ technology can be summarised as those in which changes in the RI of the process liquid can be translated into valuable process data.

“The benefits of Polaris™ refractometers extend beyond useful process measurements,” explains Jutta Hakkarainen. “This is because they come with the accuracy and long-term reliability that Vaisala customers expect. In contrast with many other inline measurement instruments, Polaris™ refractometers are simple to operate and maintain, and they are insensitive to flow rate, suspended solids, crystals, bubbles, entrained gases and sensor coating. It therefore seems unlikely that they will remain a secret for much longer.”

FOR MORE INFORMATION

Contact us for a quote email [email protected] or call +353526122722

RSS Feed

RSS Feed